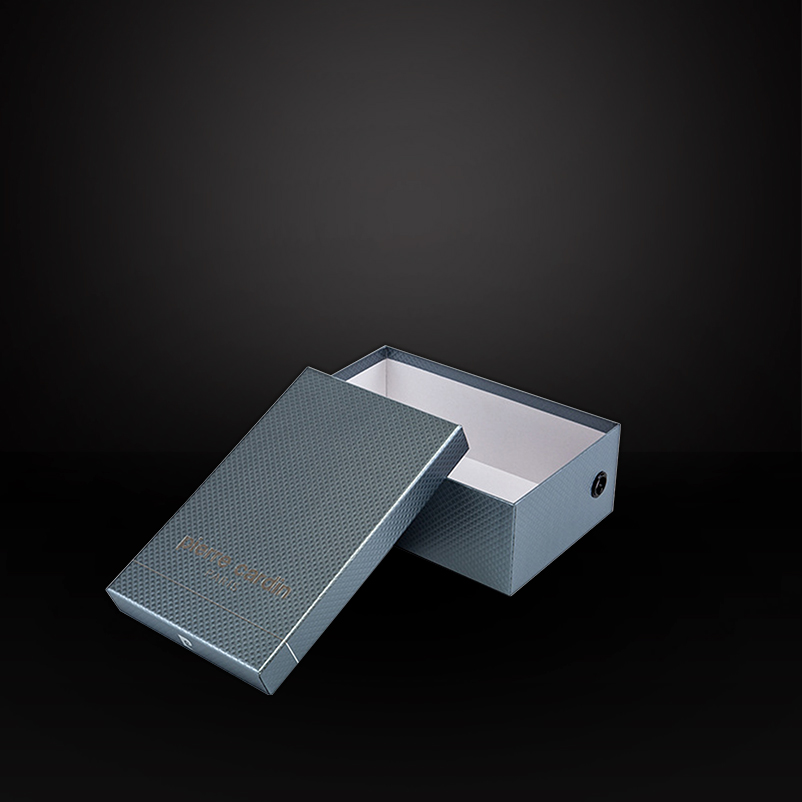

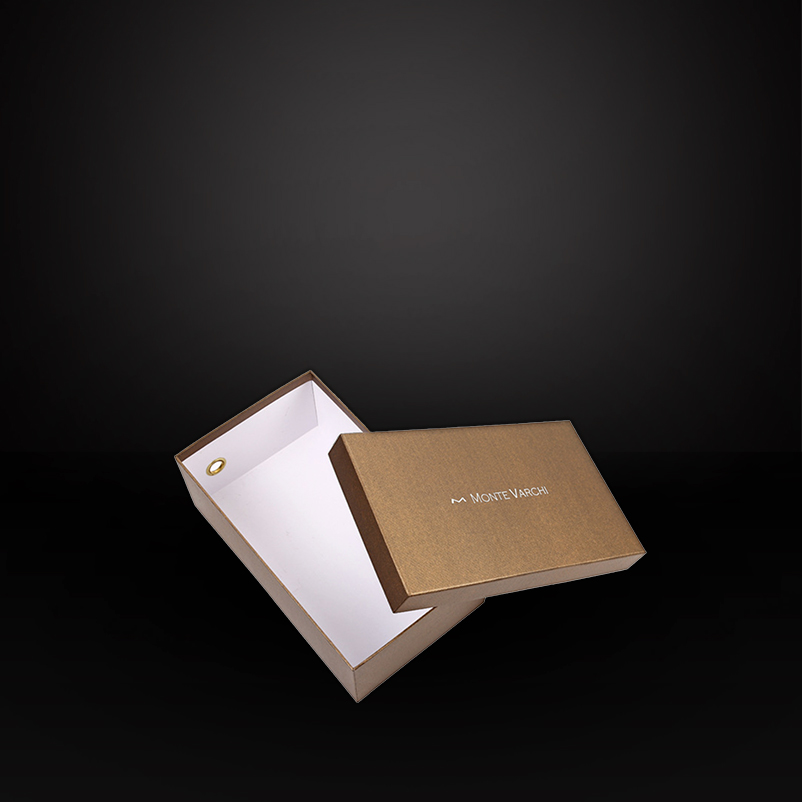

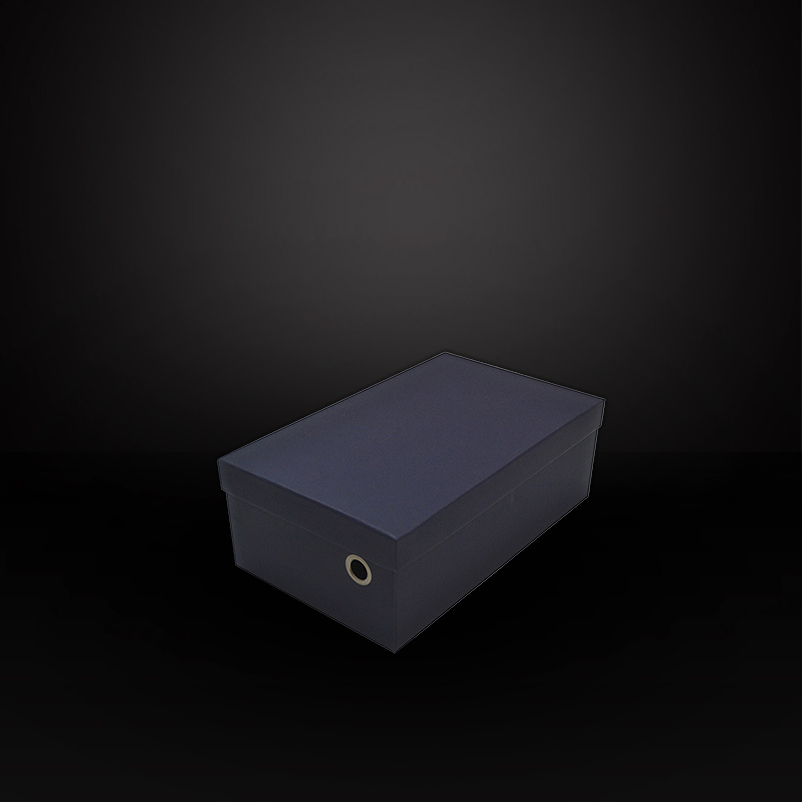

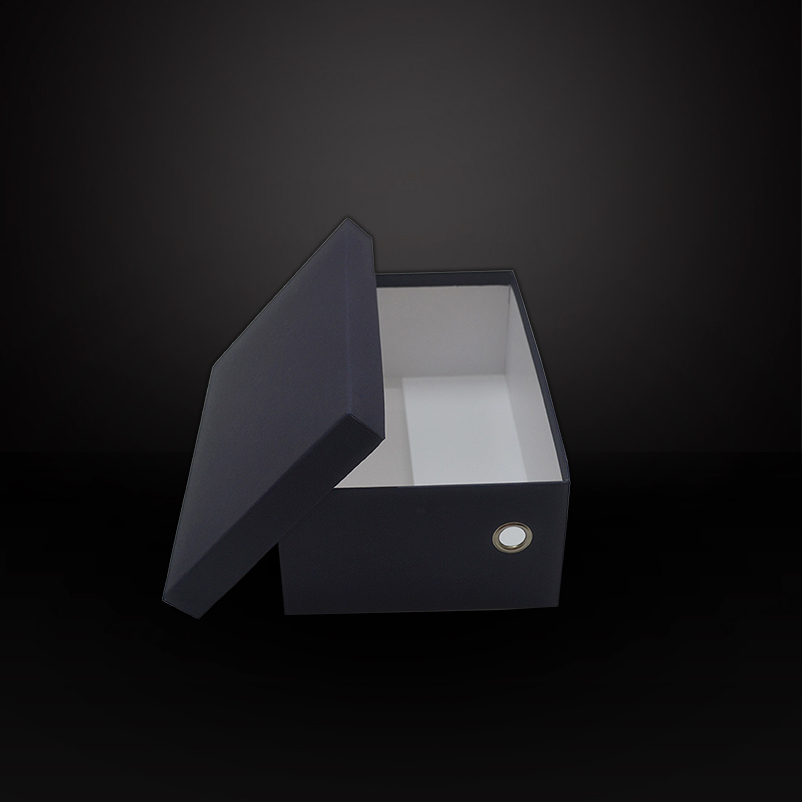

automated production lid and base corrugated shoe box with iron ring

1. Lid and base shoe box box is our star product. From cardboard die cutting, top sheet die cutting and box production, all are finished on automatic production line

2. Lid and base shoe box box is shipped with desiccant and heat shrinkable film, packed into master carton.

3. Lid and base shoe box box also can shipped and deliverd with paper bag to clients' warehouse.

4. Lid and base shoe box box 's paper uses 100% recycle with FSC certification.

5. Lid and base shoe box is made of single wall corrugated cardboard with matt lamination, gloss varnishing, silver stamping or spot UV on box surface

6. Lid and base shoe box is designed as lid and base structure, which is convenient for opening and multiple use.

7. Sample fee is free

- XTFCPP

- Xiamen,China

- Production lead time 30 days

- Production capacity 1K~10K pieces

Details

Specification:

| Material | 300g CCNB + cprrugated E flute |

| Size | any customized size you would like |

| Production process | color printing, matte lamination , hot stamping、die cutting、glue |

| Scope of use | shoe manufacturer, shoe brand owner |

We have an end-to-end packaging supply chain from design to production in China. As a global packaging customization factory, we serve industrial and brand customers. Our clients are always amazed by our packaging design ideas, creations, and services. We are so proud of our competitiveness.

At TongChangshun, thanks to the large number of OEM projects we undertook, our structural engineering team has rich experience and professional customer service. Well-trained, knowledgeable structural engineers and project designers clearly understand your needs and concerns. We always insist on providing the most cost-effective packaging design solutions and the most competitive pricing, ready to support you with any help and advice you may need. So that you can focus more on your business.

XiaMen TongChangshun printing and packaging Co., Ltd construction experts are obliged to provide you with the best box design. If you have already designed a pleasing package for your products, we will design a viable packaging die template based on your artwork. If you are still struggling with your packaging design, we will create a production-tested tooling design for you based on the dimensions you provide.

All of our models are custom made, we suggest you supply the exact sizes and create a matching die-line model. After you receive the model, please notice these three important lines marking guidelines on the die drawing:

Cut Lines: Box shapes cutting based on cut lines. Please place the artwork inside the cutting line to ensure that it is cut or covered during the cutting or assembly process. (If you need to know the exact location of the design drawing, please click to contact our structural engineer)

Bleed Lines: Allow the printed image to extend beyond this line to ensure that your artwork will not appear in unintended colors at the edges when cutting. Generally, the designer will add 2~4mm of reserved position “bleed” around the image cutting position to ensure the consistency of the finished product.

Folding lines: Keep important labels in the correct place on the artwork. Keeping a distance from these lines will ensure that your labels do not fall into the folded lines during production inadvertently.

* Please note: Die-lines will not be printed on the final packaging, they are for design details and production reference only.

Our suggestions:

If you have no idea about the package size, please provide us with your product sizes. Our construction engineers will design a suitable model of the packaging die line for you, so that your designer can design on it comfortably.

If you have already completed the artwork, we will start proofing and production based on your documents.

If your artwork needs to be printed on both sides, please let us know to determine the direction of each panel.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)